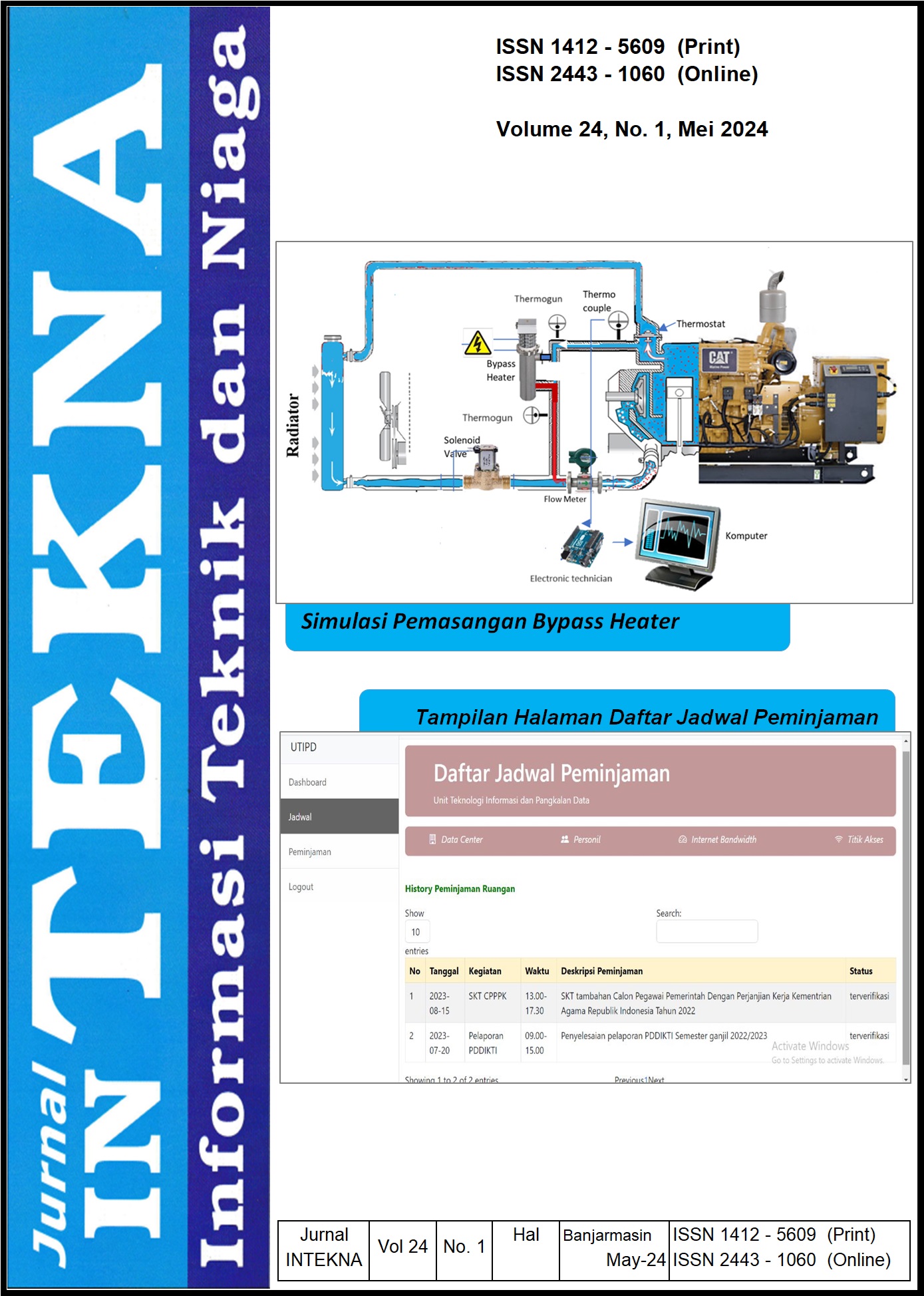

ANALISA PENGGUNAAN HEATER (PEMANAS) PADA SISTEM PENDINGIN DIESEL ENGINE TERHADAP KONSUMSI BAHAN BAKAR

DOI:

https://doi.org/10.31961/intekna.v24i1.2389Keywords:

Mesin Diesel, pemanas, konsumsi bahan bakarAbstract

Artikel ini menyampaikan perbedaan waktu dan jumlah konsumsi bahan bakar (fuel consumtion) yang dibutuhkan sebuah mesin untuk mencapai suhu kerja. Uji coba dilakukan pada generator set mesin diesel Caterpillar type C13 tanpa menggunakan pemanas, pemanas 500 watt, 1.000wattt, 1.500 watt, dan 2.354 watt. Pada pengujian ini menunjukkan bahwa penggunaan pemanas dengan daya 2.354 watt menghasikan 20% lebih efektif untuk melakukan pemanasan atau hanya membutuhkan waktu 20 menit untuk mencapai suhu optimal engine sebesar 810C - 84OC. Selain itu juga dapat mengurangi konsumsi bahan bakar atau fuel consumtion sebanyak 1,4 liter (20,9 %).

Downloads

References

Burke R,et al (2010) "Systems approach to the improvement of engine warm-up behaviour" owertrain and Vehicle Research Centre, Department of Mechanical Engineering, University of Bath, Bath, UK 2Ford Motor Company, UK https://www.academia.edu/2539033/Systems_approach_to_the_improvement_of_engine_warm_up_behaviour

Chalgren, R. D. (2004) “Thermal comfort and engine warm-up optimization of a low-flow advanced thermal management system,” SAE Technical Papers, 01-(0047.). doi: 10.4271/2004-01-0047. https://www.sae.org/publications/technical-papers/content/2004-01-0047

Chen, X. et al. (2014) “Investigation of the cold-start engine performance at a low temperature for an engine fuelled with alternative fuel,” Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 228(3), hal. 310–318. doi: 10.1177/0954407013511070. https://www.researchgate.net/publication/273882587_Investigation_of_the_cold-start_engine_performance_at_a_low_temperature_for_an_engine_fuelled_with_alternative_fuel

Coronella, C.J.; Lynam, J.G.; Reza, M.T.; Uddin, M. (2014) Hydrothermal carbonization of lignocellulosic biomass, Application of Hydrothermal Reactions to Biomass Conversion. doi: 10.1007/978-3-642-54458-3. https://www.researchgate.net/publication/260421964_Hydrothermal_Carbonization_of_Lignocellulosic_Biomass

Daniels, C. C. dan Braun, M. (2006) “The friction behavior of individual components of a spark-ignition engine during warm-up,” Tribology and Lubrication Technology, 62(11), hal. 62–69.

Deng, Y. et al. (2018) “Effec ts of cold start control strategy on cold start performance of the diesel engine based on a comprehensive preheat diesel engine model,” Applied Energy. Elsevier, 210(June 2017), hal. 279–287. doi: 10.1016/j.apenergy.2017.10.093.

Ghasemi Zavaragh, H. et al. (2017) “Optimization of heat transfer and efficiency of engine via air bubble injection inside engine cooling system,” Applied Thermal Engineering. Elsevier Ltd, 123, hal. 390–402. doi: 10.1016/j.applthermaleng.2017.04.164.

Ibrahim, T. M. et al. (2017) “Enhancing vehicle’s engine warm up using integrated mechanical approach,” IOP Conference Series: Materials Science and Engineering, 210(1). doi: 10.1088/1757-899X/210/1/012064.

https://iopscience.iop.org/article/10.1088/1757-899X/210/1/012064/pdf

“Know your cooling system” (2008) in Caterpillar. Caterillar Inc.

Kurnia, L. (2019) Mengecek data klaim pemadaman listrik PLN, Beritagar.id. Tersedia pada: https://beritagar.id/artikel/berita/mengecek-data-klaim-pemadaman-listrik-pln

Lodi, F. et al. (2020) “Engine performance and emissions analysis in a cold, intermediate and hot start diesel engine,” Applied Sciences (Switzerland), 10(11). doi: 10.3390/app10113839

https://saemobilus.sae.org/content/982645/

Luan, Y. dan Henein, N. A. (1998) “Contribution of cold and hot start transients in engine-out hc emissions,” SAE Technical Papers. doi: 10.4271/982645.

https://saemobilus.sae.org/content/2021-01-0396

Mitchell, T. et al. (2019) “Automotive thermostat valve configurations: Enhanced warm-up performance,” Journal of Dynamic Systems, Measurement and Control, Transactions of the ASME, 131(4), hal. 1–7. doi: 10.1115/1.3117183.

Mohamed, E. S. (2016) “Development and analysis of a variable position thermostat for smart cooling system of a light duty diesel vehicles and engine emissions assessment during NEDC,” Applied Thermal Engineering. Elsevier Ltd, 99, hal. 358–372. doi: 10.1016/j.applthermaleng.2015.12.099.

Nunney, M. J. (2007) Light and Heavy Vehicle Technology, Elsevier. Elsevier Ltd. doi: 10.4324/9780080465753.

https://www.taylorfrancis.com/books/mono/10.4324/9780080465753/light-heavy-vehicle-technology-nunney

Polaris Laboratoris (2020) “Overcooling Is as Detrimental as Overheating,” hal. 2–3.

https://polarislabs.com/overcooling-is-as-detrimental-as-overheating

Raju., D. et al. (2015) “Review on engine cooling system,” International Journal of Advanced Scientific and Technical Research, 7(5), hal. 335–345.

https://www.researchgate.net/publication/342158576_REVIEW_PAPER_OF_ENGINE_COOLING_SYSTEM

Sebastian, K. dan Paul, J. (2016) “Advances in cooling systems,” III(I), hal. 20–26.

Syahrir, M dan sungkono (2021), Pengaruh Penggunaan Bahan Bakar Biodisel (B30) dan Dexlite terhadap Kinerja Mesin Diesel, Jurusan Teknik Mesin Unviersitas Muslim Indonesia

Ramadhas & Hongming Xu (2017) Intake air heating strategy to reduce cold-start emissions from diesel engines Biofuels ISSN Journal homepage:: A.S.

https://research.birmingham.ac.uk/en/publications/intake-air-heating strategy-to-reduce-cold-start-emissions-from

Vasiliev, L. L. et al. (1999) “Heat storage device for pre-heating internal combustion engines at start-up,” International Journal of Thermal Sciences, 38(1), hal. 98–104. doi: 10.1016/S0035-3159(99)80020-8.

Xin, Q. (2013) “Diesel engine heat rejection and cooling,” in Diesel Engine System Design, hal. 825–859. doi: 10.1533/9780857090836.4.825.

https://www.researchgate.net/publication/288497554_Diesel_engine_heat_rejection_and_cooling

Yadav, K. et al. (2019) “Effect of coolant temperature on performance and emissions characteristics of I.C. engines: A Review,” 10(5).