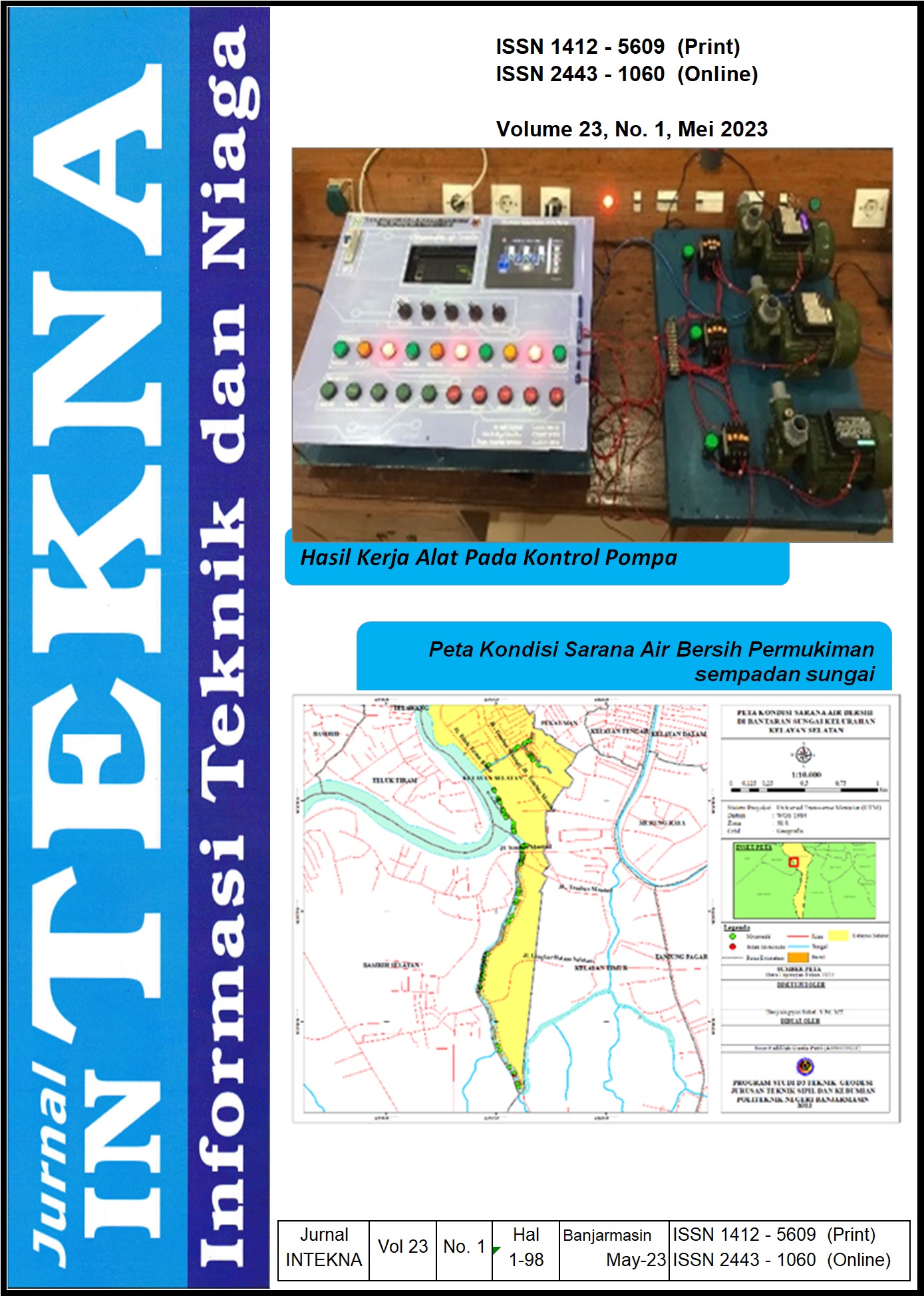

Kendali Otomatis Pengisian Tangki Air 3 Tingkat Menggunakan Monitoring HMI Berbasis PLC

Simulasi Kendali Otomatis Pengisian Tangki Air 3 Tingkat Menggunakan Monitoring Hmi Berbasis Plc

Kata Kunci:

level air, kontrol, monitoringAbstrak

Penampungan air dalam keseharian masyarakat biasanya adalah berupa tendon air. Dimana proses pengisian air kedalam tangki menggunakan system manual. Sering kali terjadi pengisian yang sia sia d kerenakan menggunakan metode manual dan bukan system secara terprogram. Pengisian sia sia adalah terjadinya buangan air yang sangat banyak. Kalo hal ini terus di lakukan, maka akan terjadi pemborosan air tanah.

Dengan latar belakang masalah yang ada ini, maka sangat perlu di buat sebuah sistem kontrol otomatis pada pengisian tangka air. Dimana Sistem kontrol otomatis ini di harapkan untuk dapat meningkatkan effisiensi secara menyeluruh, baik dalam hal penggunaan listrik, penggunaan air, serta memperpanjang usia motor pompanya.

Hasil rancangan alat yang dibuat dengan kontrol sistem otomatis pada dua buah pompa dengan tiga tangki air di dapatkan hasil yang sangat effisien. Dimana kerja kontrol di monitoring dan di kendalikan oleh sebuah HMI. Ketinggian air dalam tangki akan menginformasikan keadaan dalam tangka air baik dalam keadaan kosong maupun penuh. Ada tiga informasi yang di dapat oleh HMI, yaitu indicator level air dalam keadaan high, medium , low.

Unduhan

Referensi

M.Budiyanto, A.Wijaya, Pengenalan Dasar Dasar PLC (Progammable Logic Control),Gava Media Yogyakarta 2003

Setiawan I, PLC (Progammable Logic Control)dan Teknik Pereancangan system control, Penerbit Andi, Yogyakarta, 2006

Boltom, William, “Programmable Logic Controller (PLC) Sebuah Pengantar Edisi Ketiga”. Erlangga., Jakarta, 2004

Tri Prabowo, Panduan Belajar HMI ( Human Mechine Interface Beginner), Jakarta, 2018

Haryanto, Heri. Hidayat, Sarif “Perancangan HMI (Human Machine Interface) Untuk Pengendalian Kecepatan Motor DC” Jurusan Elektro Fakultas, Teknik Universitas Sultan Ageng Tirtayasa, 2012.